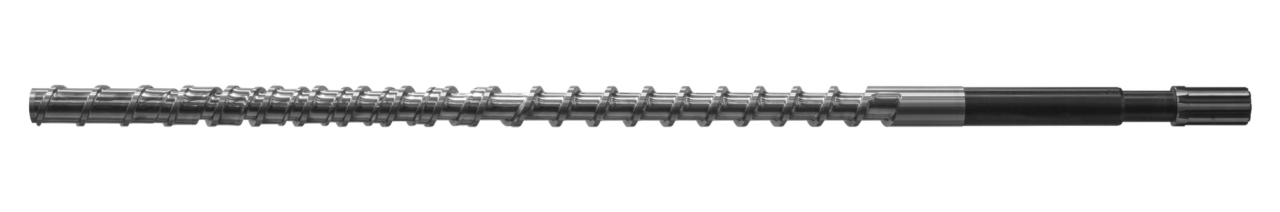

Plasticizing screws

One of the fundamental characteristics of plasticizing screws is that of having a high mixing and homogeneous melting capacity suitable for the transformed polymer.

It is for this reason that the geometric profile of the screws is a fundamental element both for the creation of a quality product and for obtaining economic advantages , reducing production waste, reducing cycle times and facilitating energy savings. .

The continuous research and development activity, combined with the deep knowledge of the lamination process and the thousands of experiences of individual customers, allow us to develop screw profiles and geometries suitable for every need and application.

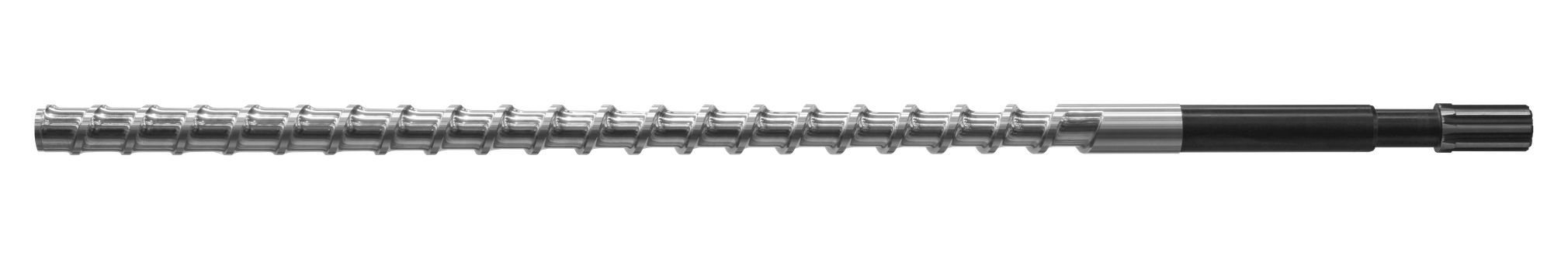

General purpose screw

Screw with universal three-zone profile , suitable for the transformation of most existing polymers. It turns out to be a good compromise for almost any application thanks to its standard profile.

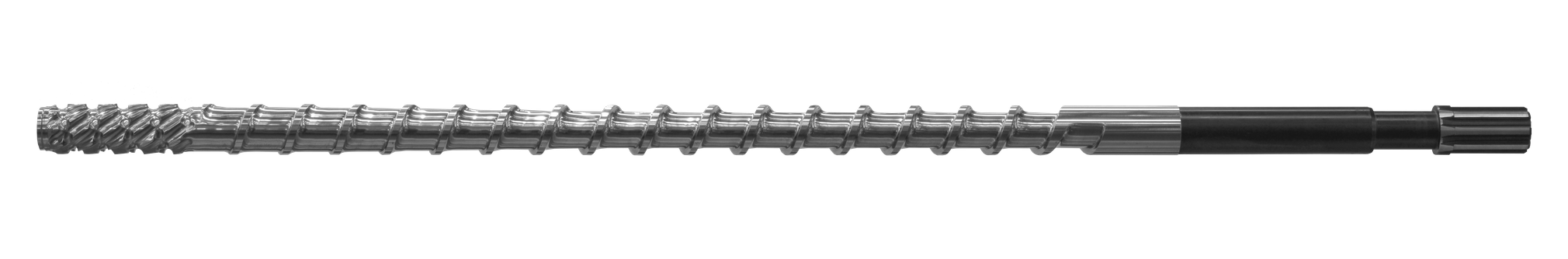

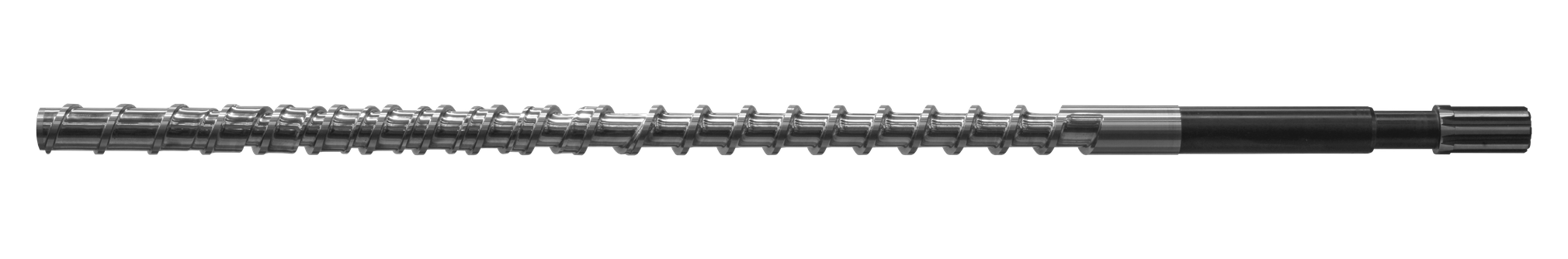

Dedicated Screws

The wide range of polymers and applications existing in the plastics processing industry requires screw profiles often dedicated to specific projects or applications : mixing screws, double-pitch screws or screws with special compression ratios, and screws with profiles created ad hoc the result of Brixia Plast ‘s experience and innovation.

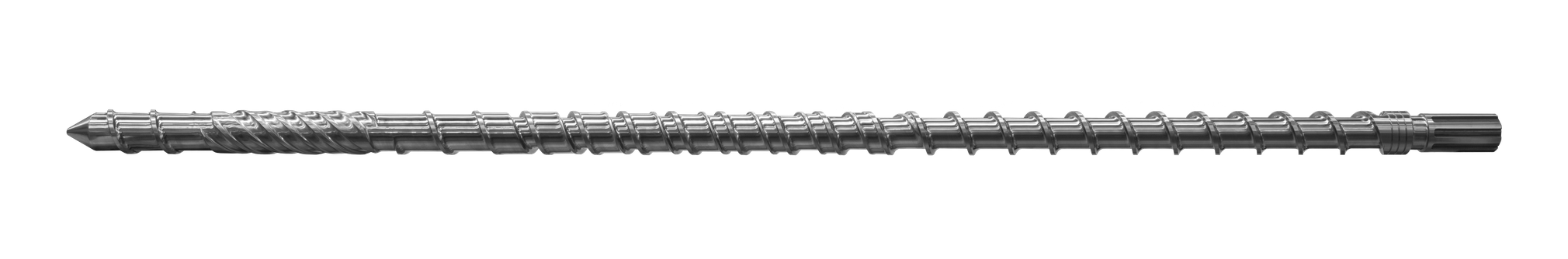

Multi Compound Screw

Screw with innovative geometry, with very high plasticizing capacity. The result of years of experience, this screw can be used with multiple polymers: from classic polyolefins (PP, PE) to technical materials (including nylon), up to transparent materials. Final mixers can be added to this screw geometry.

Multi Compound Screw

The flagship of BRIXIA PLAST’s research and development, and by now strong of a positive feedback on the market, the MULTI COMPOUND screw represents a solution with high efficiency performance, suitable for different types of polymers.

Its main advantages are as follows:

• High plasticizing capacity

• Better homogenization of the polymer and additives

• Reduction of back pressure

• Reduction of the necessary engine torque

• Reduction of molding temperatures

• Reduction of lamination time

These advantages contribute to obtaining a high quality of the molding process and of the finished products, as well as a considerable energy saving.

Steels for screws

| MATERIAL | CLASS | DIN | TREATMENT | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|---|---|

| LK3 | conventional | nitriding | 950 – 1100 HV | • | • | |

| K55 | conventional | temper | 58 – 62 HRC | •• | •• | |

| SLP | conventional | temper | 58 – 60HRC | ••• | •• | |

| VDX | dust | temper | 62HRC | ••••• | • | |

| STX | stainless steel | temper | 50 – 52 HRC | • | ••••• | |

| M390 | dust | temper | 58HRC | •••• | •••• |

Welding overlays

| MATERIAL | BASIC | HARDNESS | ABRASIVE WEAR RESISTANCE | CORROSIVE WEAR RESISTANCE |

|---|---|---|---|---|

| SPJ12 | Co | 42 – 46 HRC | ••• | ••• |

| LF5 | Fe | 58 – 62 HRC | •••• | •• |

| LF56 | No | 59 – 54 HRC | ••• | •••• |

| LF83 | Ni – Wc | 67 – 68 HRC | •••• | •••• |

Coatings and Treatments

PVD

PVD (Physical Vapor Deposition) technology is a coating process that uses vacuum systems for the vaporization of a solid metal into a plasma of atoms or molecules. These molecules, vaporized, are deposited as a coating on the surface of conventional steels and more. The technology allows to obtain very high performance coatings , with a thickness in terms of microns, which does not alter the size of the piece.

CrM

The thick chromium coating by means of a galvanic process is suggested in those plasticization cycles in which on the one hand it is necessary to reduce the friction coefficient and on the other hand protection against high corrosion and oxidation phenomena is required.

NpR

The NpR treatment is a thermochemical treatment (Fe O base) proposed to counteract wear by increasing the surface hardness and decreasing the surface friction coefficient . It reaches a hardness between 850 and 900 HV and has a thickness of 4-5 µm. This treatment is mainly used on screws of important dimensions , where it is not possible, for reasons both of technological and economic limitations, to propose a coating with PVD technology.

Comparison table

| MATERIAL | TECHNOLOGY | COEF. FRICTION | THICKNESS | HARDNESS | COLOR |

|---|---|---|---|---|---|

| CroX | PVD | 0,3 | 2 – 5 µm | 2000 – 2500 HV | rainbow |

| TiN | PVD | 0,45 | 2 – 5 µm | 2000 – 2500 HV | gold |

| I open | PVD | 0,35 | 2 – 5 µm | 2800 – 3000 HV | grey |

| CrM | Galvanic treatment | 0,17 | 0.2 – 0.3 mm | 900 – 1000 HV | silver |

| NpR | Thermochemical treatment | 0,45 | 4 – 5 µm | 1200 HV | black |