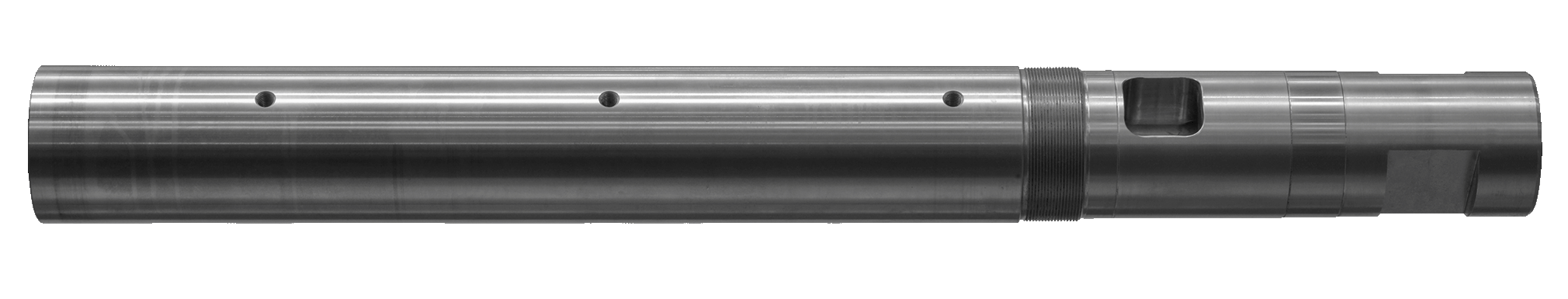

Cylinders

The plasticizing cylinder is an extremely important component in the plasticizing process as it must give strength to all the other components of the unit, guaranteeing resistance to high pressures and wear.

Our goal is to face the challenges of a constantly evolving sector and to constantly supply products of the highest quality , using the best steels of European origin (available on the market).

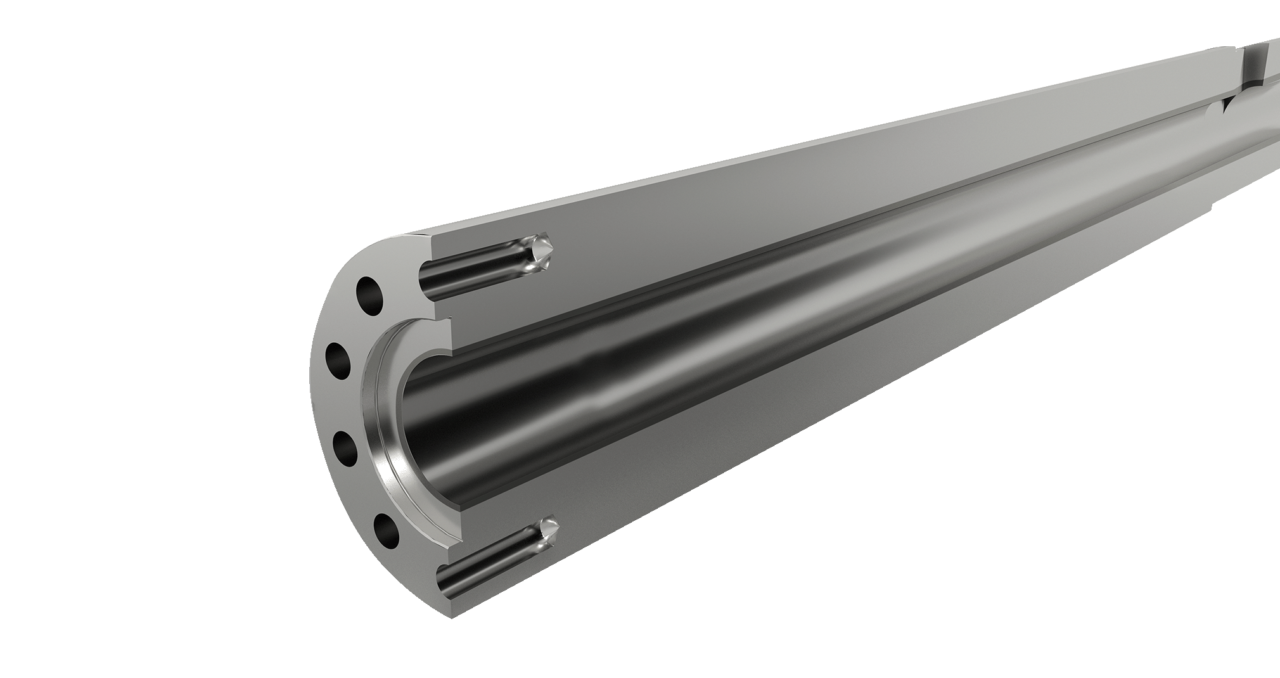

Bimetallic cylinders

BRIXIA PLAST offers a range of bimetallic cylinders covering the different wear classes. Using certified raw material produced with latest generation centrifugation systems, our cylinders guarantee high quality standards , surfaces free of distortions and porosity and superior durability even in extreme working conditions.

Nitrided cylinders

This type of cylinder is suitable for the transformation of those polymers that do not cause abrasive and corrosive wear. This material requires a heat treatment of gaseous or ionic nitriding depending on the use and reaches a hardness between 950 and 1100 HV.

| MATERIAL | CLASS | DIN | TREATMENT | HARDNESS | RESISTENCE ABRASIVE WEAR |

RESISTENCE CORROSIVE WEAR |

|---|

| bimetallic | B12 | Fe | Ni BC | 65 – 68 HRC | •• | •• |

| bimetallic | B21 | Fe | Cr Mo Ni BC | 65 – 68 HRC | ••• | •• |

| bimetallic | B25 | No | Cr Mo Co BW c C | 60 – 65 HRC | ••••• | •••• |

| nitrided | NTR | 1,8509 | 950 – 1100 HV | • | • |

The best materials for the best performance: certified bimetallic cylinders, of European origin, to guarantee quality, reliability and durability in any condition.