- +39 030 68 54 456

- info@brixiaplast.com

- Via Bonfadina 35 - 25046 Cazzago San Martino (BS) Italy

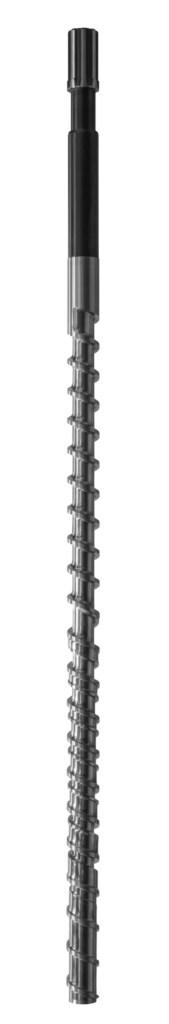

Our plasticizing screws are designed to optimize polymer mixing and melting. The innovative geometric profile reduces waste and shortens cycle times, thereby increasing energy efficiency and providing considerable economic benefits.

Our general-purpose screws feature a universal three-zone profile, ideal for processing most polymers. These screws provide an effective and versatile solution for various standard applications, ensuring quality and reliability.

We produce screws for special applications, including degassing models specifically for PVC, extrusion, rubber, thermosets and biodegradable materials. These screws are designed to meet special needs, with profiles and geometries born of experience and continuous innovation.

The Multi Compound screw is the flagship of our technology, with a geometry that greatly increases plasticizing capacity. Suitable for working with a wide range of polymers, this screw includes options for final mixers that improve material homogenization. Benefits include reduced back pressure, lower molding temperatures and reduced plasticizing times, contributing to significant energy savings

PVD (Physical Vapor Deposition) technology is a coating process that uses vacuum systems of vaporizing a solid metal into a plasma of atoms or molecules. These molecules, vaporized, are deposited as a coating on the surface of conventional steels and beyond. The technology yields very high-performance coatings with a thickness in micron terms that does not dimensionally alter the part.

Thick chrome coating by galvanic process is suggested in those plasticizing cycles where, on the one hand, it is necessary to reduce the friction coefficient and, on the other hand, protection against high corrosion and oxidation phenomena is required.

NpR treatment is a thermochemical treatment (Fe O base) proposed to counteract wear by increasing surface hardness and decreasing the surface friction coefficient. It reaches a hardness between 850 and 900 HV and has a thickness of 4-5 µm. This treatment is mainly used on large screws, where it is not possible, for reasons of both technological and economic limitations, to propose a coating with PVD technology.

Brixia Plast S.r.l.

Subject to management and coordination activities by Sintesi 421

REG.IMPRESE DI BRESCIA NR.04350050987

NR.REA : BS-607724 CAP.SOC. E. 100,000.00 I.V.

AMAPLAST is the national association of plastic and rubber machinery and mold manufacturers. Founded in 1960, non-profit, it is part of CONFINDUSTRIA and brings together about 170 members.

ISO 9001 Certification

Rapid technological progress and the globalization of markets have made process-oriented quality management a necessity and a challenge for our companies.